The objective of the common strategy paper is sharing the recognition of important issues about smart manufacturing. The paper should lead into a statement and (strategic) action plan for important issues about smart manufacturing in terms of Germany-Japan cooperation.

1. Long-term view and focused topics of smart manufacturing

Standardisation is a key issue for the success of a smart manufacturing vision of the industries in Japan and Germany. Internet of Things (IoT)/Industry 4.0 requires an unprecedented degree of system integration across domain borders, hierarchy borders and life cycle phases. This is only possible if it proceeds from standards and specifications based on consensus. It is critical to consider the standardisation as a basis for open and inter-operable system architecture for industrial implementation of the vision of smart manufacturing. As world leaders in the field of Manufacturing technology and production systems, Germany and Japan have spent strong effort for promoting smart manufacturing research, developments and industrial implementations. Germany and Japan have agreed to cooperate on standardisation in the field of smart manufacturing by sharing the long -term view for smart manufacturing and focusing on common pertinent topics.

2. Current situation

The cooperation partners met twice in Germany on October 7 and December 12 2016. They formed a joint working group and exchanged information on international standardisation for smart manufacturing. The following activities and contributions will be expected and planned for 2017.

2.1 Current key events

In conjunction with G20 Conference:

2.2 Activities and fora on international standardisation

Collaboration options between Germany and Japan with respect to the standardisation activities are in progress with the above standards developing organisations (SDOs), while coordinating the standardisation of related elements, which affect suitability for integration into system of systems.

3. Fundamental direction of Germany-Japan cooperation

3.1 Development of detail use cases

For the future views and/or topics agreed between Germany and Japan, ideal operation images should be described in text as “Use Cases”. Use Cases need to show which functions of organisation, human and production units would work closely together in how effective manners, then would deliver what values to whom in manufacturing activities.

Use Cases are important base scenario IOS to analyse and identify technical requirements for deployment, expansion and new developments of the standards afterwards.

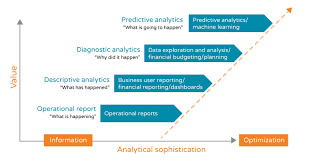

3.2 Use of the reference models in the focused areas

3.3 Identification of standardisation requirements

In the areas where new standards needed, it is required not only to clarify sufficiency of international standards but also list technical requirements that the standard should satisfy. For this purpose, the above process can used to identify the requirements. Firstly, use cases are decomposed into group of functions, which realise the use cases. Then, it is possible to define data models to be shared among the functions and interfaces between the functions for the use cases. Germany and Japan cooperation will benefit those works of analysing use cases.

4. Support of standardisation works

Reference models and architectures are essential for further standardisation work in smart manufacturing. Reflecting the diversity of need and applications, several models have been proposed, and such models set a comprehensive framework for the conceptual and structural design of smart manufacturing systems. In this context, the proposed work on mapping and harmonising the existing models to achieve higher interoperability should fostered.

Standardisation is critically important for realising smart manufacturing towards global and sustainable developments. Germany and Japan have agreed to cooperate in the developments of International standards and SDO activities by sharing information and setting up consistent strategy and action plans as stated in this paper.