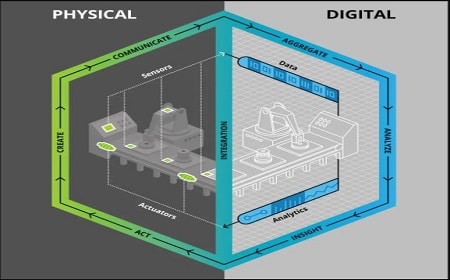

A digital twin is an advanced portrayal of a process, product, or service. They utilize ongoing information to make sensible recreations, engaging organizations to screen, test, and plan enhancements to their products, equipment, and processes.

Digital twins have been accessible for almost twenty years, yet propels in innovation, joined with cheaper focuses, have brought about a restored center around the advantages of an advanced twin technique. The Internet of Things (IoT) is one headway that has helped upgrade their precision and advantages. IoT is an idea that permits businesses to handily introduce sensors on physical objects (hardware, products, and so on) to gather information. These sensors catch data, for example, working conditions, preparing speeds, temperature, or pressure. At that point, the sensors send that information to a cloud-based framework that is utilized to examine and anticipate execution and/or conduct.

Digital twin innovation is changing the substance of manufacturing industry and accordingly diminishes the costs; control resources and diminishes the downtime caused by equipment failure. Computerized coordinating piece of an actual article in enterprises assumes an essential part in Industrial IoT. This technology is likewise expanding additional opportunities for each business around the world. Digital copy uses innovations, for example, computer generated reality by utilizing the information and graphics modeling for impeccably making a virtual model of any equipment.