Leak testing is the process of checking a system for leaks (a defect). Leak testing can be achieved using various leak detection methods and is employed to test for defects in products and to ensure the proper function and maintenance of industrial systems and pipelines.

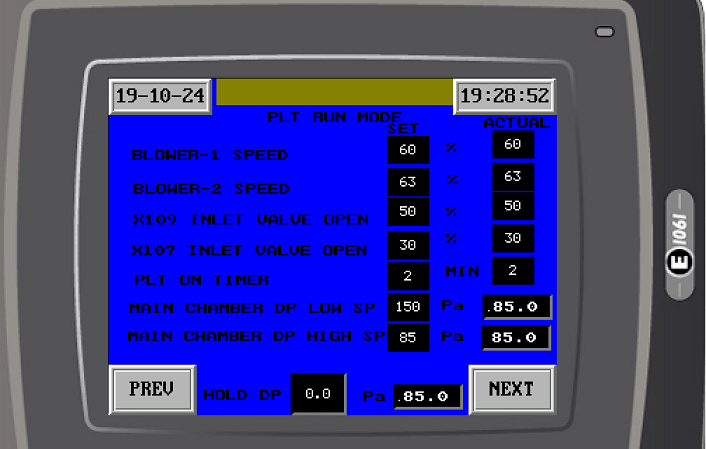

The pressure is to maintain constant within the permissible limit in two chambers. By considering the constant pressure and leakage test is performed. For this operation we used a plc based automated logic with HMI interface.

There are two type tests are performed with this machine, (1) Aeriation test, (2) Fogging test

If the pressure is not with in the permissible limit a popup is displayed in the HMI as pressure leak test fail and need to press stop button in HMI. After stopping, the machine will go to aeriation test directly without executing the fogging test. After the aeriation mode completed the machine come to normal position.

If the pressure is within the limit then it shows in HMI as leak test pass. And we can continue to start the fogging test. In this blowers and valves are open simultaneously. After completion of fogging cycle time automatically machines will go to aeriation mode in this mode also same devices will operate as same as fogging mode but the difference is blowers speed and inlet valves open position which are set in individual. Finally, the machine will go the run mode after completion of the cycle.

+91 9030070085

+91 7801063999

#501C, Bankers Chambers,

A S Raju Nagar, Kukatpally,

Hyderabad Telangana -500 072.