Sintering machines are designed for sintering the diamond segments, wire saw beads, the diamond grinding wheel and other kinds of segments for diamond tools. This machine is composed of main frame, hydraulic system, electronic unit, thermometric element and cooling system etc. The equipment can achieve automatically the whole sintering process, including controlling temperature and pressure, adjusting Temperature Set Points in PID Controller, together with operating conveniently and controlling accurately.

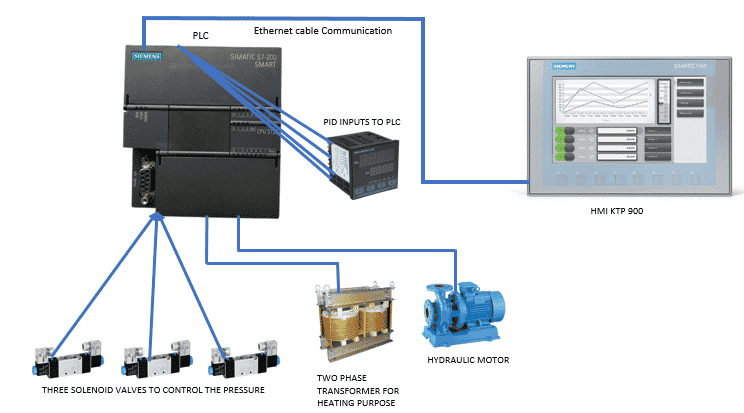

Sintering machine is equipment where diamond tool segments are pressed by using hydraulic pressure and through heating process. Here we used SIEMENS PLC ST20 and SIEMENS HMI KTP900 for Automation of the machine. The automatic working process of the machine is given below:

The segments are placed on the hydraulic piston and pressing the Cycle Start Button to start the process. Now hydraulic Motor starts and Piston starts moving up as a result the down hydraulic piston plate and upside plate touches with segments in between them. A two-phase Transformer Starts to heat the segments up to certain point of the temperature. After reaching the certain specified temperature, with the PID controller the temperature is maintained constant for 5 minutes, then the transformer shuts down. After that the hydraulic piston comes down with heated segments and these segments are now placed under the cooling cylinder, which is present beside the main hydraulic piston and the segments are placed again on the Hydraulic Piston. Likewise, the process of sequence repeats continuously.

+91 9030070085

+91 7801063999

#501C, Bankers Chambers,

A S Raju Nagar, Kukatpally,

Hyderabad Telangana -500 072.