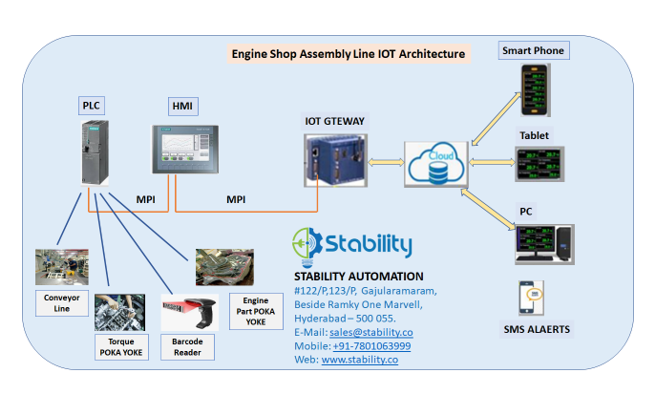

This project is to provide the automation for Manufacturer Assembly Line Monitoring using IoT Solution.

It consists of Assembly line equipment i.e., Conveyor line, Torque system, Barcode Readers and Engine Poko Yoke Systems are connected to PLC System, Here PLC system Controls the entire line operation and HMI will display local line status to the operators. From HMI through MPI port communication connected to Ewon Gateway to get the data from the PLC and HMI system, Engine Assembly line conveyor line having total 28 stations, each station having different parts assembling activities with Poko Yoke System and each station with different system calls for stoppage those are Material, Maintenance, Quality & Production calls. Alarms and Poka yoke also configured in the controller. From the System Assembly Line Production data, Poka Yoke, Alarms & Calls in each station wise data display in Ewon IoT System Dashboard and also configured SMS Alerts to Maintenance team. Along with above data TPM and TBM data remotely monitoring also provided in Dashboard. Each Station Wise all data storage in reports are generated, it is helping customer to reduce the Number of stoppages the line and giving clear visibility of production data and reasons for stoppage.

For Enquires : +91 9100451116/17/18

For Technical Support : +91 9100451119

#501C, Bankers Chambers,

A S Raju Nagar, Kukatpally,

Hyderabad Telangana -500 072.