Prediction of tool wear is essential to maintaining the quality and integrity of machined parts and minimizing material waste, for sustainable manufacturing. So, monitoring of Machine Tool’s life online gives a quick action to operator to change it and understand its performance.

In any machine operation the features of tools, input work materials, machine parameter settings will influence the process efficiency and output quality characteristics. A significant improvement in process efficiency may be obtained by process parameter optimization that identifies and determines the regions of critical process control factors leading to desired outputs or responses with acceptable variations ensuring a lower cost of manufacturing. The cutting conditions i.e. Speed, Feed and Depth of cut plays an important role in the efficient use of a machine tool.

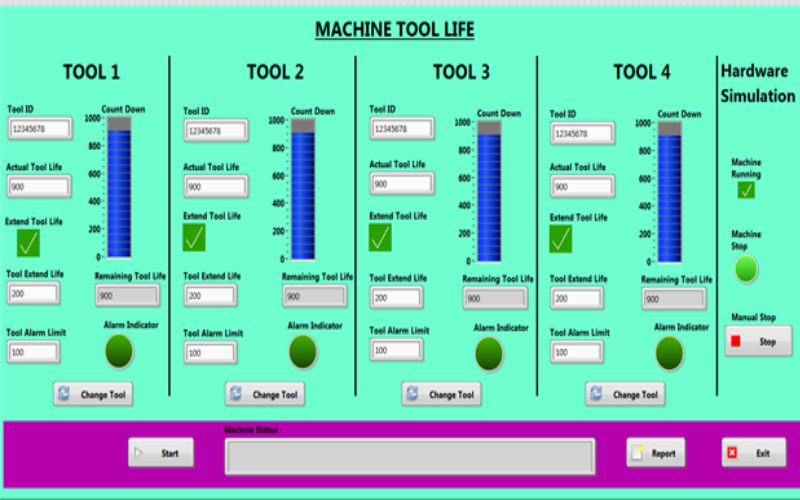

In this application we have communicated a PLC with LabVIEW with Modbus TCP/IP protocol and application is developed in LabVIEW software to monitor Tool life of machine. This application is Web based Application and user can access it from anywhere. With this application we can send Email-alerts to no. of Users. And the operator can change the Tools of a machine when its life expires. In this way the efficiency and quality of the end product can be maintained as well as the Machine’s productivity can be increased.

+91 9030070085

+91 7801063999

#501C, Bankers Chambers,

A S Raju Nagar, Kukatpally,

Hyderabad Telangana -500 072.