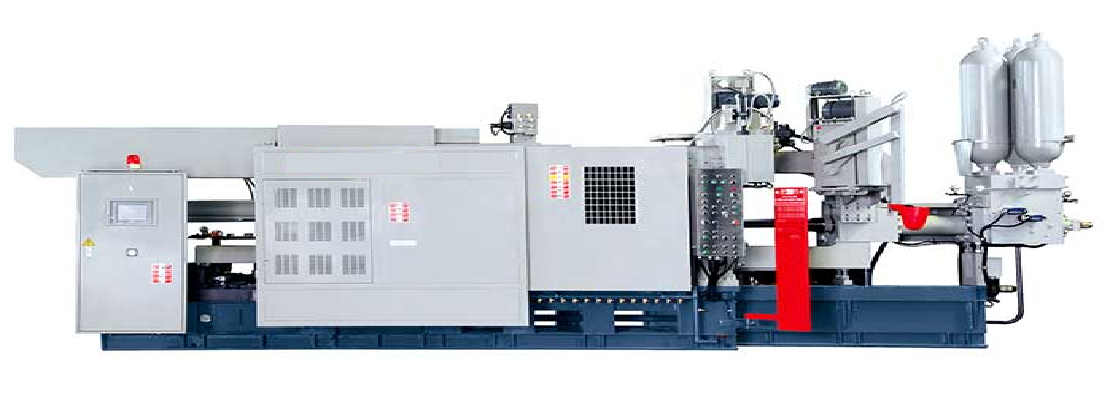

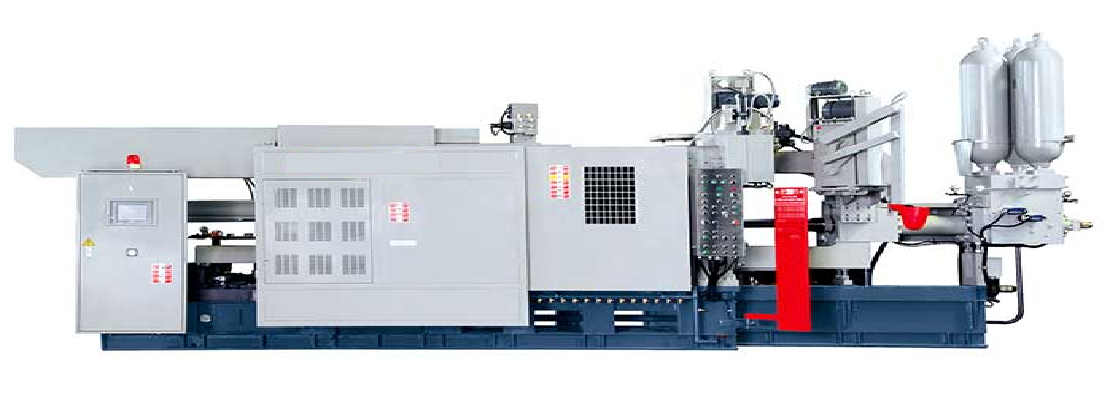

Die casting machines are the main part of Automobile Diecast industries. Analyzing the performance of those machine can increase the life expectancy, process, production and reduce the maintenance cost. Operators will get clear idea about the whole machine performance.

In large machines the breakdowns are high due to giant in size. But when the breakdowns happen, we need to know the reasons why it happened and what are the causes for the break downs.

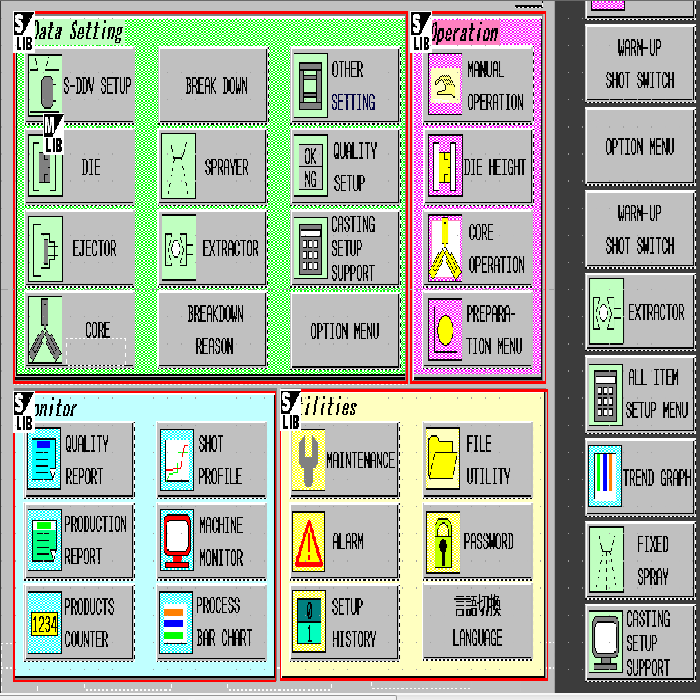

In this process we have used HMI. And we have developed screens for recording the important paraments of the machine-like metal temperature, die alignment, pressure, production count, extractor, ejector, etc. With this parameters report has been generated to check the quality of the end product and as well as the tools life used in the machine. Alarms will be generated after certain count of production, to do maintenance checkup. All this data is stored in the HMI and gives clarity about how the machine is running and to prevent from breakdown. All problems is stored in HMI along with Date and Time so the operator can get to know the breakdown reason and how it has overcome previously. With this process we can able to increase the production and reduce the maintenance cost. This data will much useful in SCADA & OEE projects for predictive maintenance.

+91 9030070085

+91 7801063999

#501C, Bankers Chambers,

A S Raju Nagar, Kukatpally,

Hyderabad Telangana -500 072.