Endurance Testing is a software testing type, where a system is tested with a load, extended over a significant amount of time, to evaluate the behavior of the system under sustained use. The purpose of the testing it to ensure that the application is capable enough to handle the extended load without any deterioration of response time.

Goals of Endurance Testing for Transformer:

Primary Goal is to check any leaks in the transformer.

To discover how the transformer may respond under sustained usage.

To ensure that after a long period, the system response time will remain the same or better than the start of the test.

To manage the future loads, we need to understand how many additional resources (like temperature, pressure and vacuum parameters) are necessary to support usage in future.

Endurance testing is generally done by either overloading the system or by reducing certain system resources and evaluating the consequences.

It is performed to ensure that defects do not occur after what is considered to be a relatively “normal” usage period.

Implementation of Endurance Test:

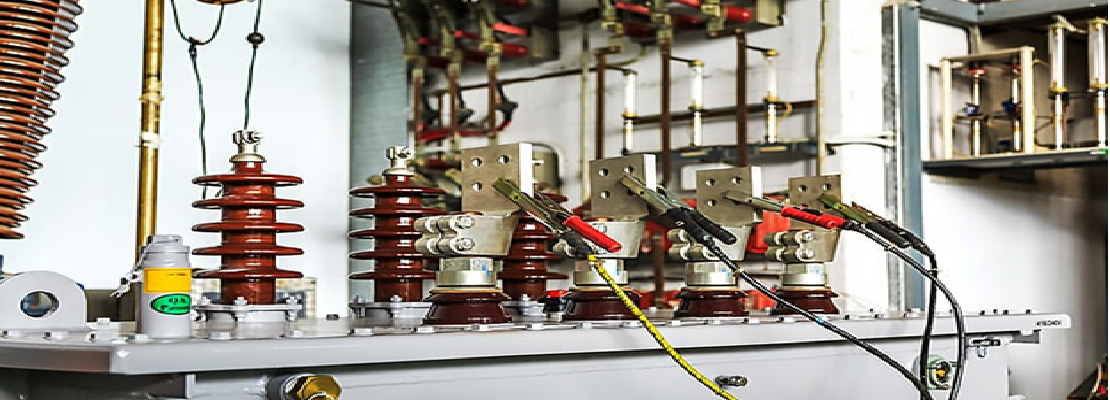

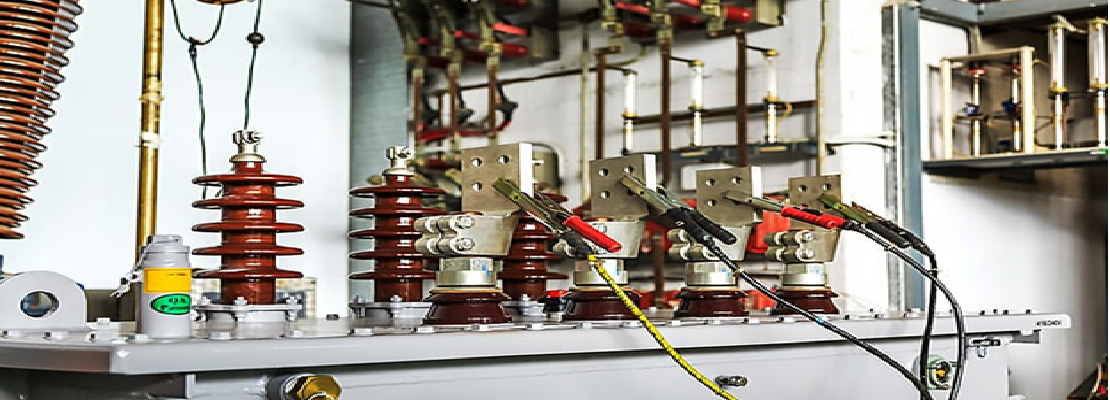

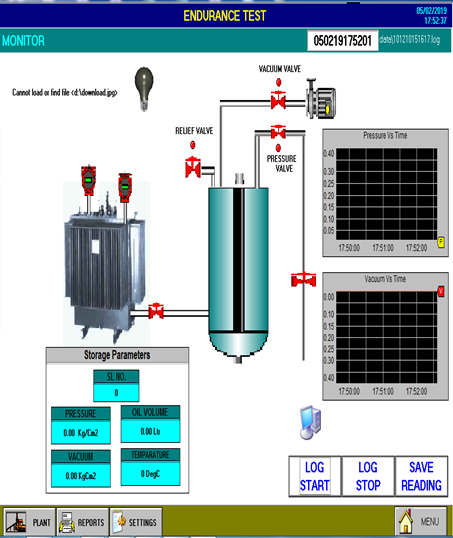

In the Transformer Testing, we are collecting data like Oil temperature, pressure, and vacuum. To collect this data, we have used external sensors like RTD’s, pressure sensor, vacuum measuring sensor. All this data is seen on the meters that are connected to the transformer. The data is collected as per the set points which is then sent to the PLC from there it is sent to the SCADA system. By this data Transformer is calibrated or tested.

+91 9030070085

+91 7801063999

#501C, Bankers Chambers,

A S Raju Nagar, Kukatpally,

Hyderabad Telangana -500 072.