Die casting is a metal casting process that is characterized by forcing molten metal under high pressure into a mold cavity. The mold cavity is created using two hardened tool steel dies which have been machined into shape and work similarly to an injection mold during the process. After this process we required to remove the unwanted attached die and wash it for the removal of unwanted material on the surface of the product.

Washing is the final stage of the Die casting process. As the casting will be mixture of 2 to 3 elements and when it is molded some extra or unwanted molding will be attached to the component. And the surface will also be rough. After going through all the process of casting it will finally will be washed in the Industrial washing machine where all the unwanted material will be removed.

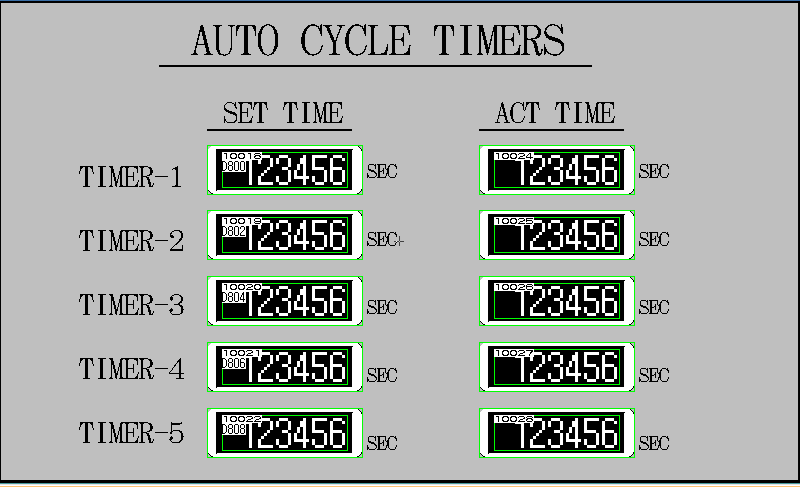

At the final stage of the casting process, the molded die is placed inside the automated washing machine. Normally by washing these components will removes the dust and oil particles present in it and it will clean and shine the product. The component is placed in the trolley and it is moved inside the chamber. When the cycle starts, the chamber door is closed and water is released on the components and after some time intervals hot water, cold water is poured simultaneously. After completion of cycle the door is opened and the trolley is pushed outside of the washing chamber.

+91 9030070085

+91 7801063999

#501C, Bankers Chambers,

A S Raju Nagar, Kukatpally,

Hyderabad Telangana -500 072.