Paper has become a basic material we can’t imagine a day without paper. In this process speed control/ speed synchronization of drying & press mechanism place a key role, otherwise the paper will break / quality will be reduced & Power Saving Improves.

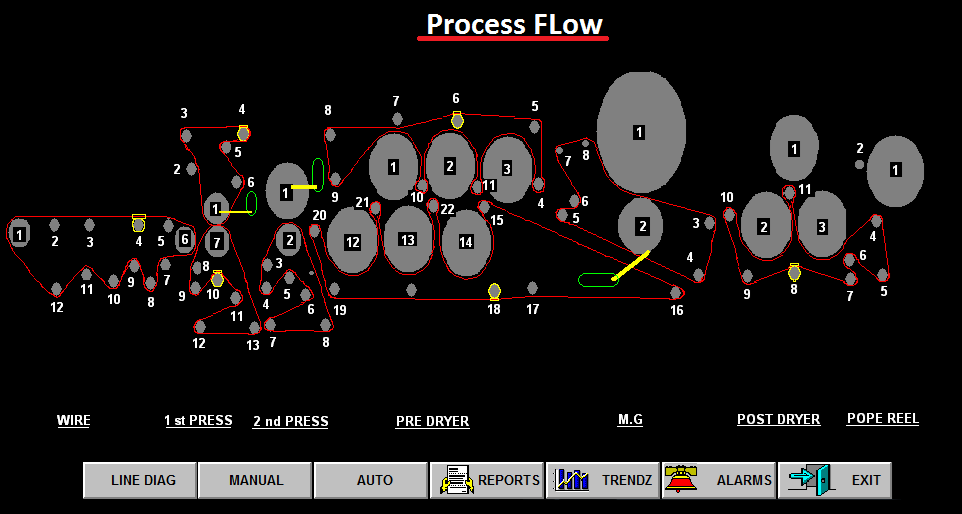

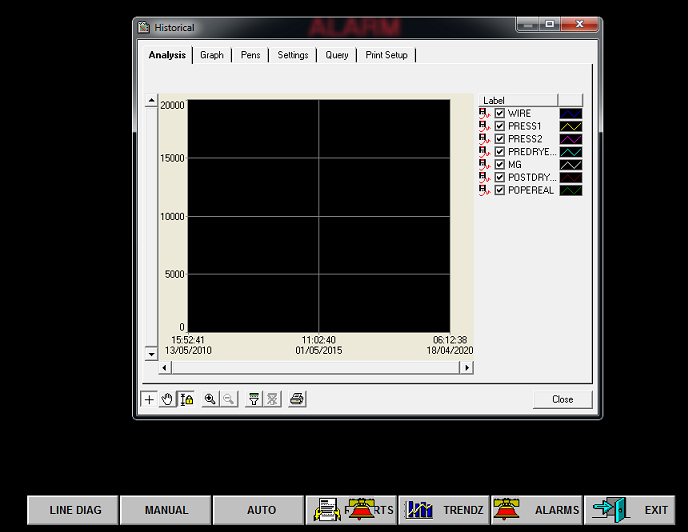

A key factor in Paper Plant is Paper Rolling Mechanism, in this high-quality series of steam heated drying drum cylinders are used to Drying the paper to remove the water content down to a level of about 6%, where it will remain at typical indoor atmospheric conditions. Here Steam enters the end of the dryer head (cylinder cap) through a steam joint and condensate exits through a siphon that goes from the internal shell to a center pipe.

In this mechanism press cylinder speed can place a key role, VFD (variable speed drive systems) provided for individual press section to maintained / synchronize the speed of sections & that speed-control the process with exceptional accuracy. Each of the drive systems has to operate at a different, yet coordinated and highly precise speed. If they don’t, the web (paper) will break, reducing productivity and impairing product quality. & power saving also possible by using VFD’s.

+91 9030070085

+91 7801063999

#501C, Bankers Chambers,

A S Raju Nagar, Kukatpally,

Hyderabad Telangana -500 072.