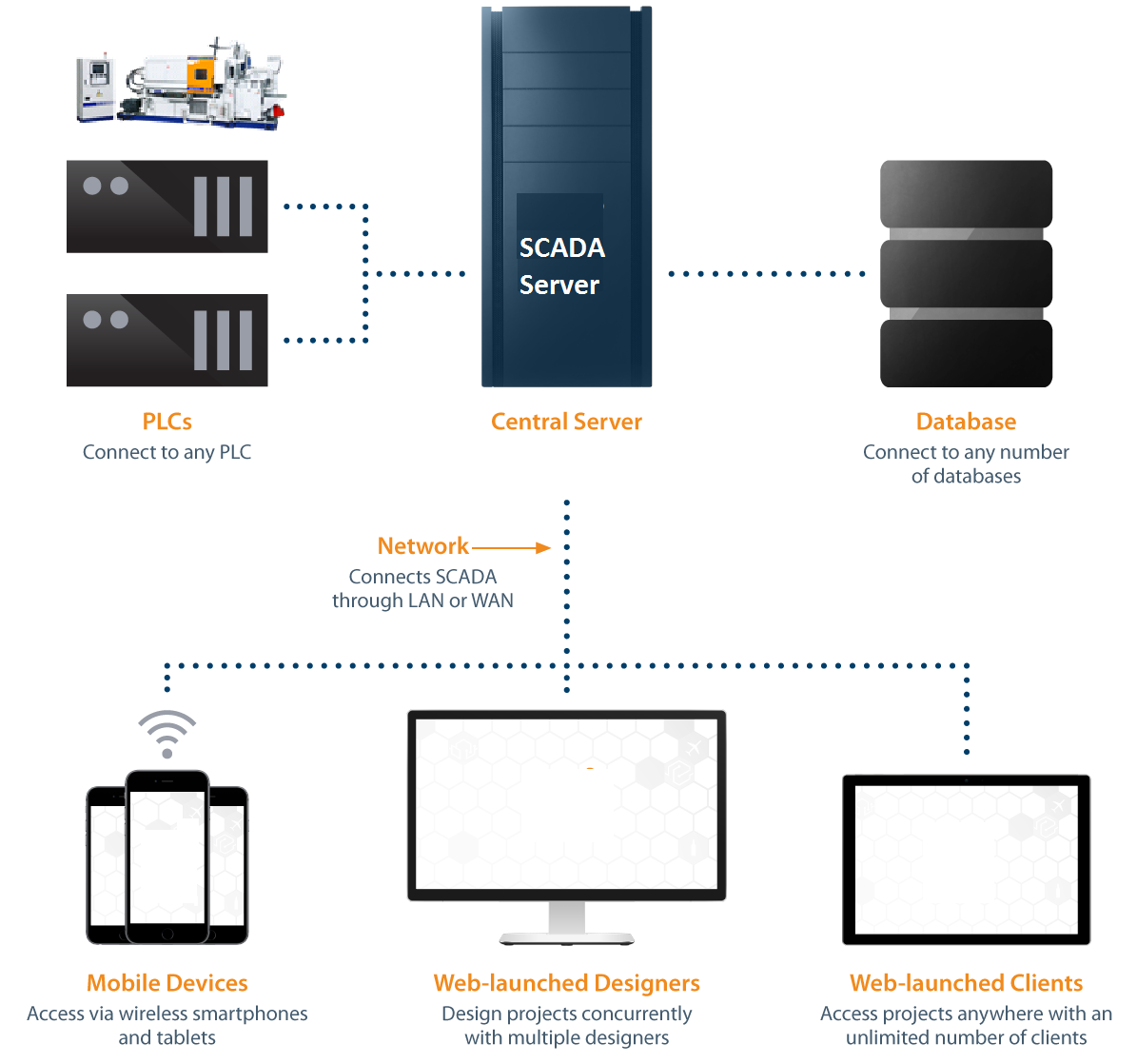

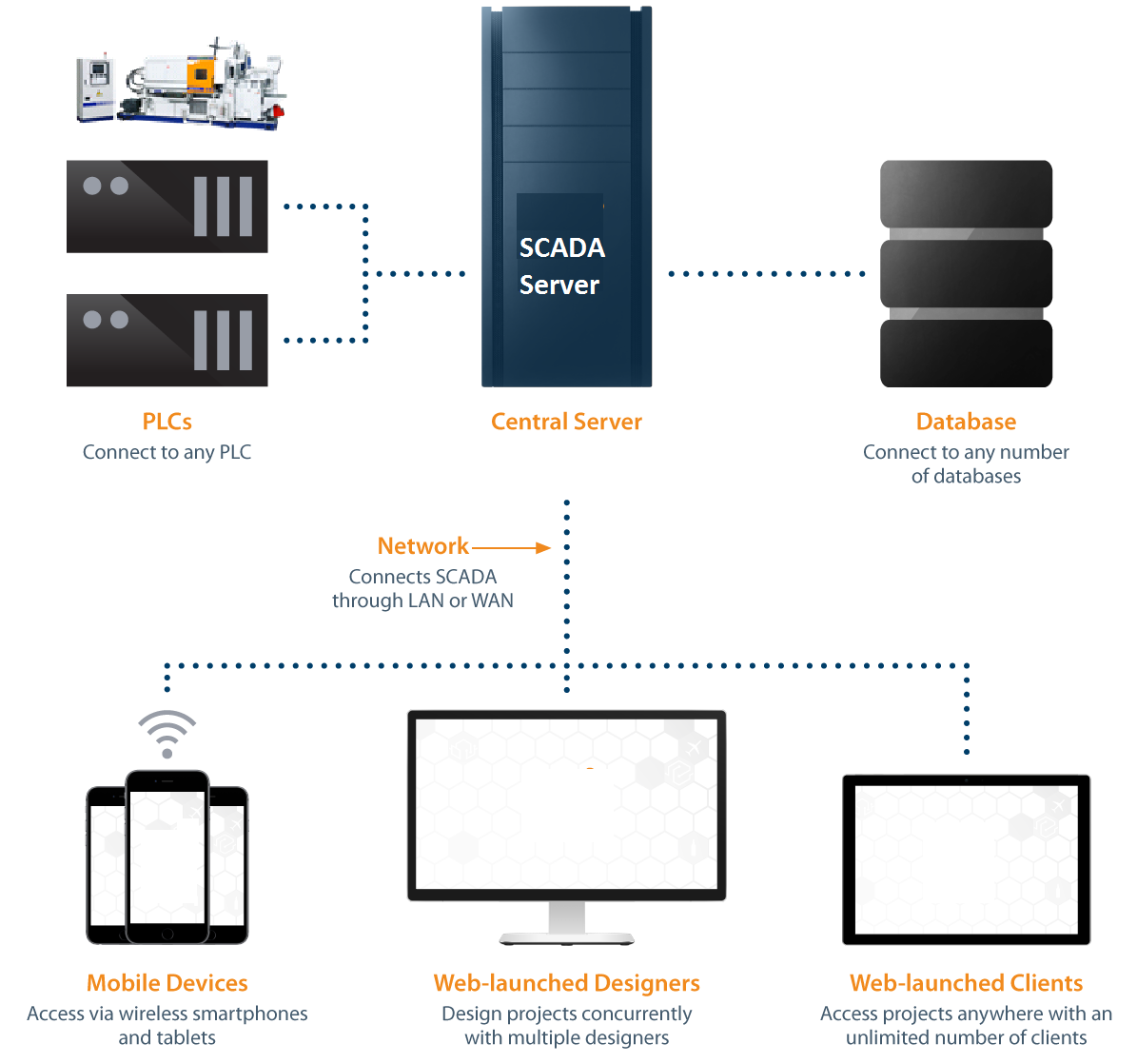

Generally, SCADA system is a centralized system which monitors and controls entire area. It is purely software package that is positioned on top of hardware. A supervisory system gathers data on the process and sends the commands control to the process. SCADA systems are used to monitor and control the equipment’s/machines in the industrial process which include manufacturing, production, development and fabrication.

Challenges: Below are the current challenges in any industry may phase during production:

During machine breakout, it is taking lot of time to identify problem due to unavailability of data.

Data required for lean methods to find problem root cause.

Unable to trace sequence of activity’s performed during problem.

Manual entry of Production reports.

Limitation to the Trends & Alarms in current system.

Altering system not available incase of Problems.

Centralized Plant Monitoring System is Not available

Approach:

By considering current challenges we found a suitable solution, which can help to resolve problems we are facing i.e. by Introducing SCADA system with below mentioned approach.

Implementation:

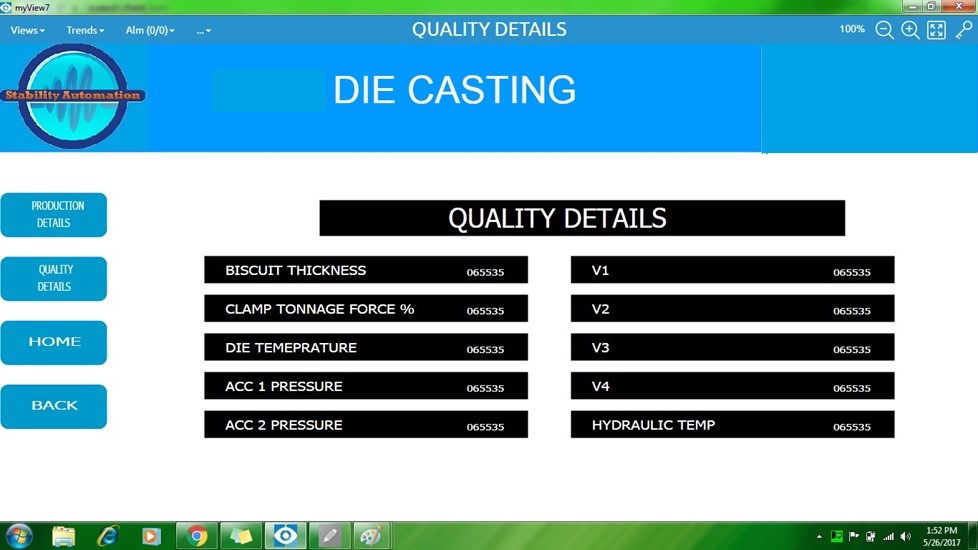

We have Impleted a SCADA system which uses uses computers, networked data communications and graphical user interfaces for high-level process supervisory management, but uses other peripheral devices such as programmable logic controllers and discrete PID controllers to collect data.

The SCADA system allows operators to change the set point for the parmaeters, and enable alarm conditions in-case of loss of prameters such as flow, temperature, pressure etc., and the conditions is displayed and recorded. The SCADA system monitors the overall performance of the loop. The SCADA system is a centralized system to communicate with both wire and wireless technology to Clint devices. The SCADA system controls can run completely all kinds of industrial process.

Adantages:

+91 9030070085

+91 7801063999

#501C, Bankers Chambers,

A S Raju Nagar, Kukatpally,

Hyderabad Telangana -500 072.