Traceability is the ability to track every part and product throughout the manufacturing process, from the moment when raw materials enter the factory to the moment when final products are shipped. Quality System Tracability and Data Capturing Solution is very Important in Manufacturing Industry to understand problems.

Traceability data is quite simple, being the build record of all events that have occurred and have had an effect on a product.

Data Capturing & traceability can provide many benefits in terms of impact and added value to the companies that implement it. Such as:

Governance: Ensure the traceability of upstream data to provide owners and data sources with quality and access control results.

Conformity: Provide regulatory authorities with information regarding the Quality & Quantity.

Change Management: Enabling users and developers to understand the impact of modifying certain data on downstream systems and reports.

Development of Solutions: Improve design, testing and deliverables of better quality. This is achieved through the sharing of traceability metadata, glossaries, and relationship among distributed development teams.

Storage Optimization: Provide as an input to archive decisions and provisions, an overview of the data being accessed and indicate where, how often and by whom access is permitted.

Data Quality: Improvement of the quality scores defined by the application of business rules and standardization on data, added to the metadata population as input of algorithms and decision making.

Problems Resolution: Helps in the analysis of root causes in repair-type processes.

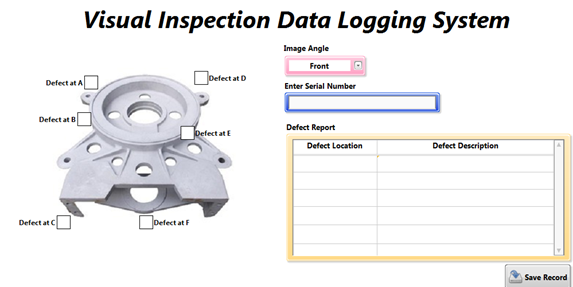

LabVIEW based Application software developed for Defect Traceability in Automotive Quality testing for capturing entire quality details of product and this detail useful for understanding defect details and to address issues.

+91 9030070085

+91 7801063999

#501C, Bankers Chambers,

A S Raju Nagar, Kukatpally,

Hyderabad Telangana -500 072.