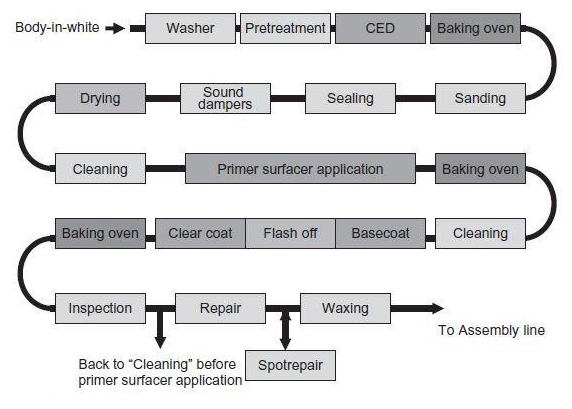

Paint shop is the main hart in automotive manufacturing, this application requires preparation and primer steps to ensure proper application. A basecoat is applied after the primer paint is applied. Following this, a clearcoat of paint may be applied that forms a glossy and transparent coating. The clearcoat layer must be able to withstand UV light.

This Process takes up to 15 to 20 hours to treat each new vehicle in the Paint Shop, a process that begins by passing the body shells through a series of dip tanks designed to stop corrosion. This dipping cleans and prepares the metal for painting, and provides protection in areas vulnerable to corrosion and damage.

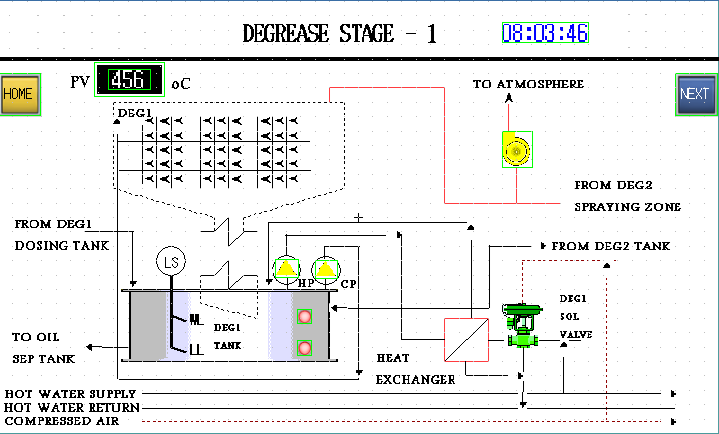

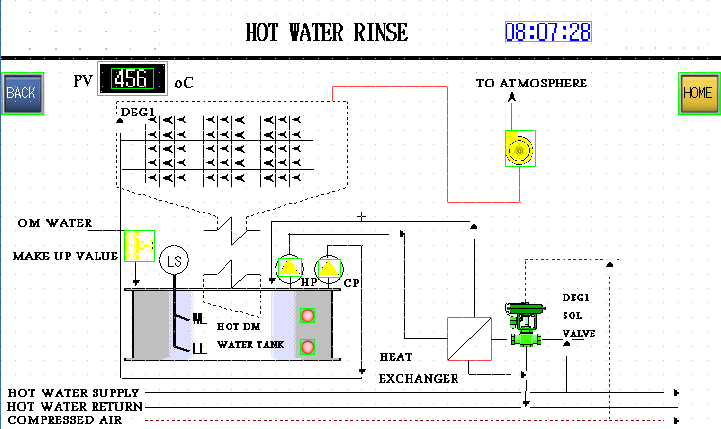

HMI plays a key role in this process, to monitor & control the Quality, Line speed, process talk time & Trouble shooting. Successfully done Up gradation of old absolute HMI in new advance model HMI without any process loss /breakdown time with all advance features like rich animation & alarm features, etc.

This upgrade will provide the latest HMI hardware and software, providing a reliable solution and replacing a potentially obsolete platform. The fully integrated and tested HMI and control system solution reduces installation and commissioning time and increases HMI quality. The HMI application software is engineering change controlled and archived to provide recovery services in the event of an HMI computer failure. The latest HMI application versions provides faster replacement of computer hardware as well as access to latest security patching and operating system support.

+91 9030070085

+91 7801063999

#501C, Bankers Chambers,

A S Raju Nagar, Kukatpally,

Hyderabad Telangana -500 072.