An assembly line is a manufacturing process (often called a progressive assembly) in which parts (usually interchangeable parts) are added as the semi-finished assembly moves from workstation to workstation where the parts are added in sequence until the final assembly is produced. By mechanically moving the parts to the assembly work and moving the semi-finished assembly from work station to work station, a finished product can be assembled faster and with less labor than by having workers carry parts to a stationary piece for assembly. Thus, Online Status of Automotive Assembly line gives immediate action and prevent break down and down time of Manufacturing Process.

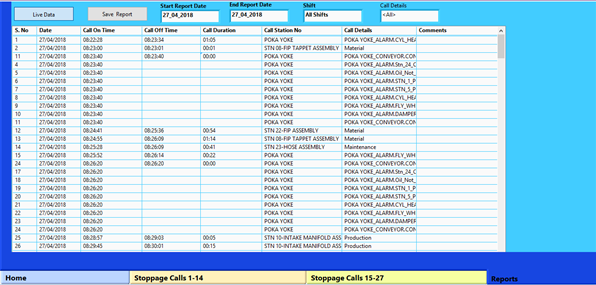

The design for an assembly line is determined by analyzing the steps necessary to manufacture each product component as well as the final product. All movement of material is simplified, with no cross flow, backtracking, or repetitious procedure. Work assignments, numbers of machines, and production rates are programmed so that all operations along the line are compatible. Online Status with Production details with Periodic and Shif wise, Stope calls for Qulaity, Production, Material and Maintenace developed for customer to get live status of assembly line with total calls on each line gives complete picture to take correct action to avoid break downs.

Using LabVIEW software developed an application which can give better visibility of shop floor and reporting for analysis.where LabVIEW offers a graphical programming approach that helps you visualize every aspect of your application, including hardware configuration, measurement data, and debugging. This visualization makes it simple to integrate measurement hardware from any vendor, represent complex logic on the diagram, develop data analysis algorithms, and design custom engineering user interfaces.

+91 9030070085

+91 7801063999

#501C, Bankers Chambers,

A S Raju Nagar, Kukatpally,

Hyderabad Telangana -500 072.