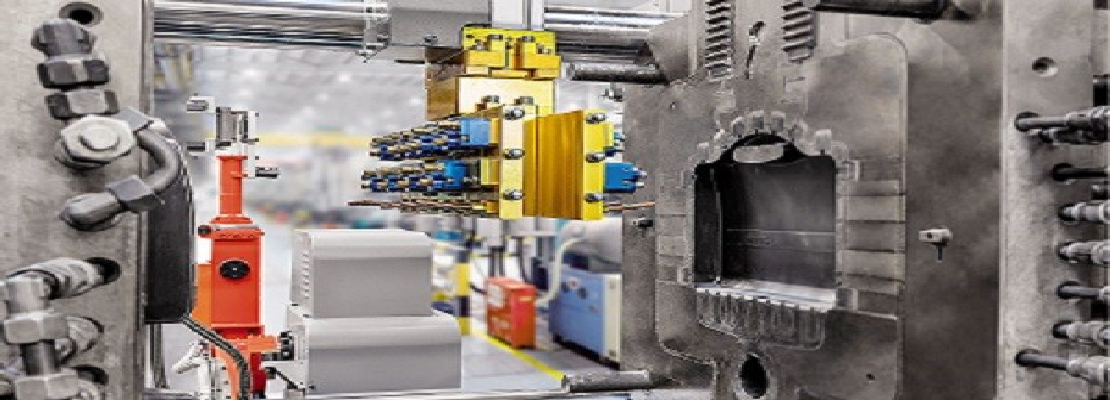

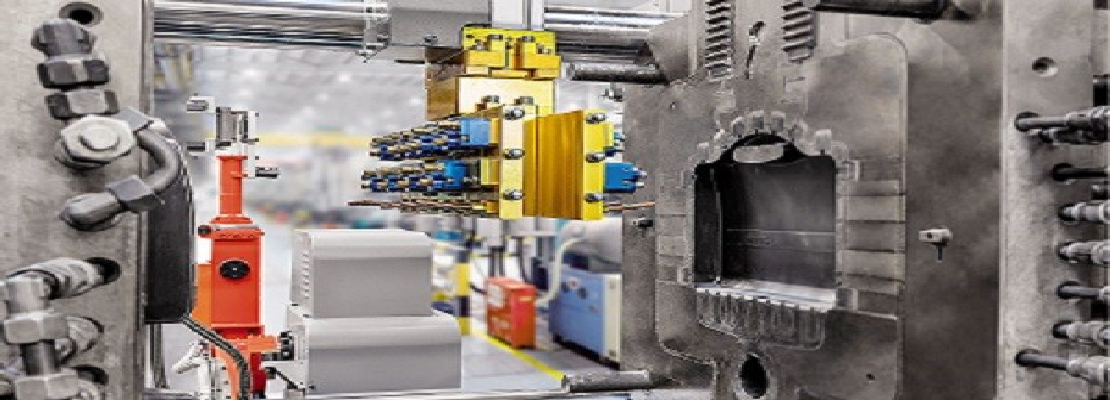

Die casting is a metal casting process that is characterized by forcing molten metal under high pressure into a mold cavity. The mold cavity is created using two hardened tool steel dies which have been machined into shape and work similarly to an injection mold during the process. Most die castings are made from non-ferrous metals, specifically zinc, copper, aluminum, magnesium, lead, pewter, and tin-based alloys. Depending on the type of metal being cast, a hot- or cold-chamber machine is used.

After injection of die casting, the dies are opened and the robot is used to took the molded aluminum material for the future processes.When the robot removed the molded aluminum, the spraying will happen. In this two servos are used. One of the servo is used for front & back and another servo is used for up & down. Hence when the spraying system is ready for spray. First the system is moves forward by using one of the servo and then it moves to downwards. When the water spraying system is moves downwards the valves will open & start spraying by moving up & down. This will helps to removes the contamination or any reaming particles attaches with die that will damages to another die. This water spraying system is very useful for production system.

+91 9030070085

+91 7801063999

#501C, Bankers Chambers,

A S Raju Nagar, Kukatpally,

Hyderabad Telangana -500 072.