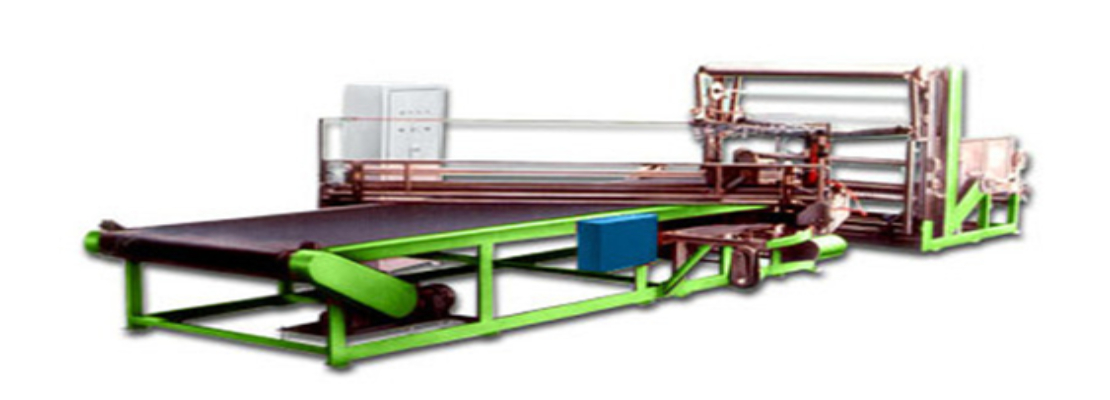

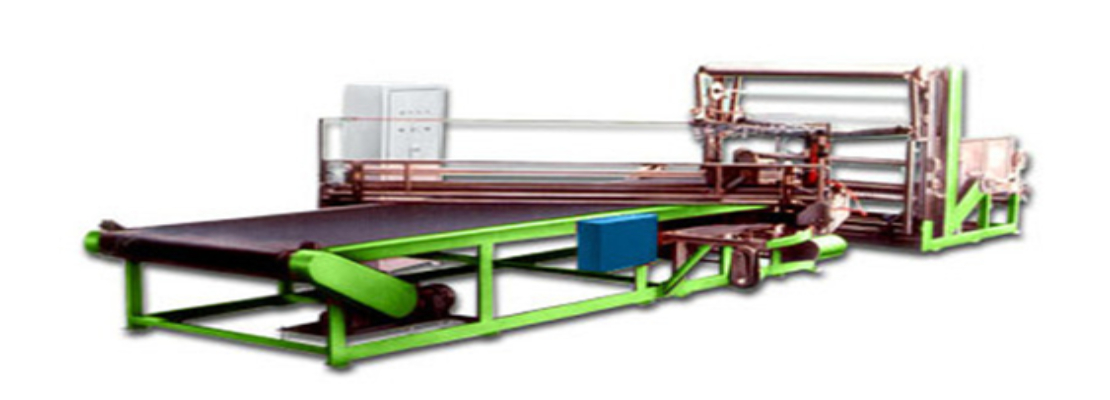

Bias cutters are used in the rubber industry, for example, for bias cutting relatively short lengths of rubberized tire building fabric from a continuous strip of the same, and more especially it relates to bias cutters of the horizontal type. They usually are equipped with a pitman and pawl and ratchet means for advancing the stock periodically to the cutting means, and the latter moves in-operatively back to point of starting after each operative stroke. In such bias cutters it has been difficult to obtain the extreme accuracy of cutting that is desired, it has required considerable time to alter the apparatus to cut lengths of different widths, and the cutting of relatively wide strips at high speed.

The calendared fabric cut to specified width and angle, using the machine commonly known as ‘Bias Cutter’. It gives strength to the tire to contain the inflation pressure. The number of layers is decided based on the inflation pressure, bias angle, optimum modulus gradation etc. The bias-ply tire is also called the cross-ply or conventional tire. In this tire the cords in adjacent plies cross the circumferential centerline of the tire at opposite and approximately equal angles. The angle which the cords in the tire makes with respect to the centerline of the tire is one of the most important parameters in a bias tire.

For maintaining the accuracy in the length and angle Servo system is used for cutting process. In the HMI the operator can set the different length and angles according to their requirement. A PLC System is used to control the Conveyor and take the input from the sensors to help the servo system in the cutting process. The accuracy of cutting width of bias can be ±1.0 mm and ±0.5 mm tolerance respectively. Cutting angle can be adjustable by gear motor. Bias Cutter with convenient and simple design, Two-Sides Bottom Control, is easy operation for workers.

+91 9030070085

+91 7801063999

#501C, Bankers Chambers,

A S Raju Nagar, Kukatpally,

Hyderabad Telangana -500 072.