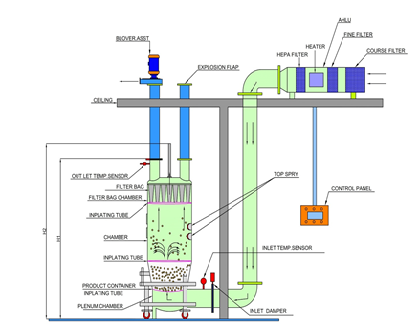

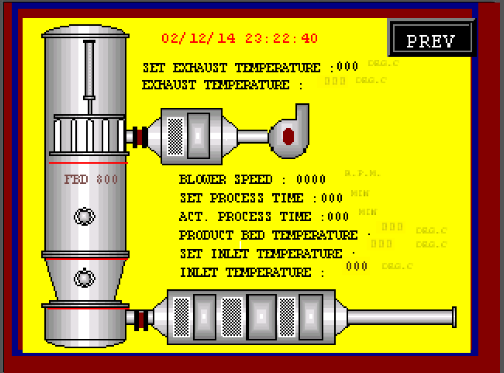

Fluid bed dryer is a Pharmaceutical Equipment which will be used in the process of , it useful for Fast and Homogeneous Drying it involves control of different process parameters, in order to achieve precise measurement and accurate control of process we used PLC and HMI system.

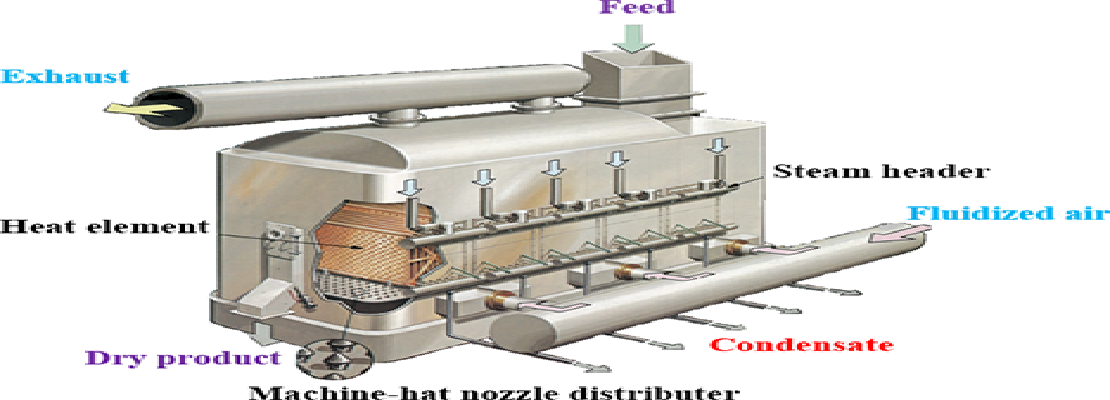

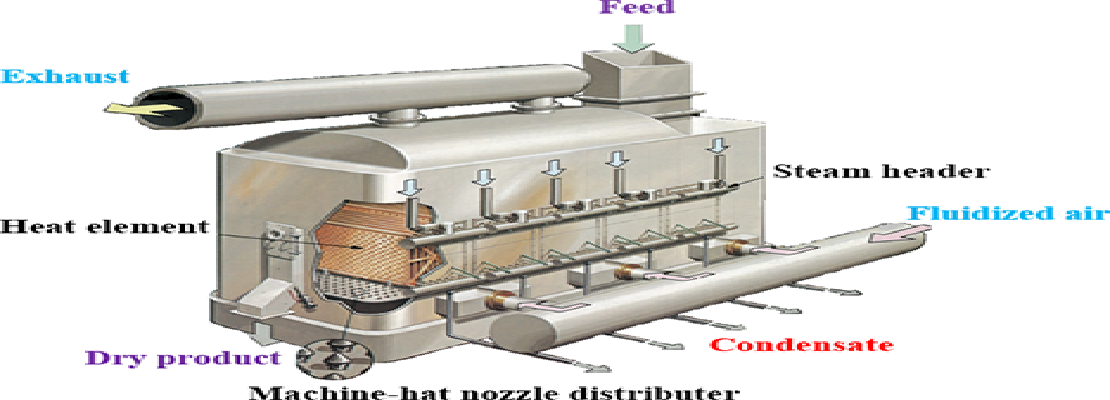

Fluid bed dryer works on a principle of fluidization of the materials. In fluidization process, hot air or gas flow is introduced through the bed of solid particulates. This gas or air will move upwards through the spaces between the particles. As the velocity increases, upward drag forces on the particles increase and at a stage become equal to the gravitational forces beneath. Hence the bed is said to be fluidized and the particles are suspended in the fluid.

A fluid bed dryer is a kind of equipment which can be used for applications like drying of powders, mixing of powders and agglomeration. This is efficiently employed for applications in chemical, pharmaceutical, dyestuff, foodstuff, dairy and various other process industries. Fluid bed dryers are often employed with the spray dryers and granulation systems for effective drying, mixing, granulation, finishing and cooling of powdered substances. These are often preferred over rotatary dryers for drying and cooling a wide range of polymer materials which require precise control of residence time and temperature for effective processing.

Here PLC system used to measure process parameters and control based on Programming written using ladder logic and HMI act as user interface for operate to monitor process values and change set points based on requirement.

+91 9030070085

+91 7801063999

#501C, Bankers Chambers,

A S Raju Nagar, Kukatpally,

Hyderabad Telangana -500 072.