The Polishing Machine is used to polish Granite Slabs which are used in housing constructions. The Brush Heads spin at high speed. Grinding and polishing bricks are attached to rotating heads for grinding and polishing purpose.

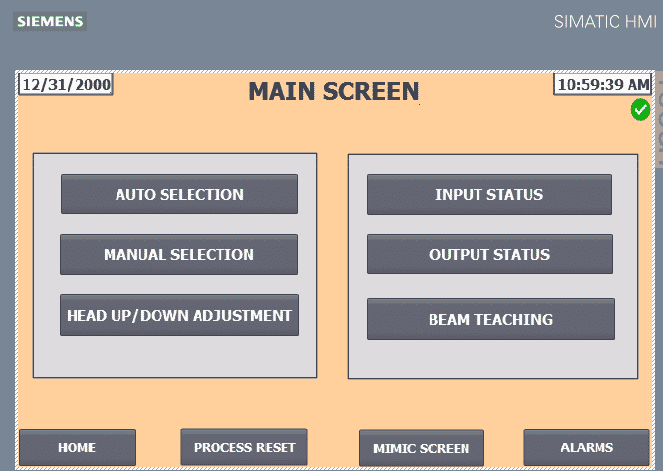

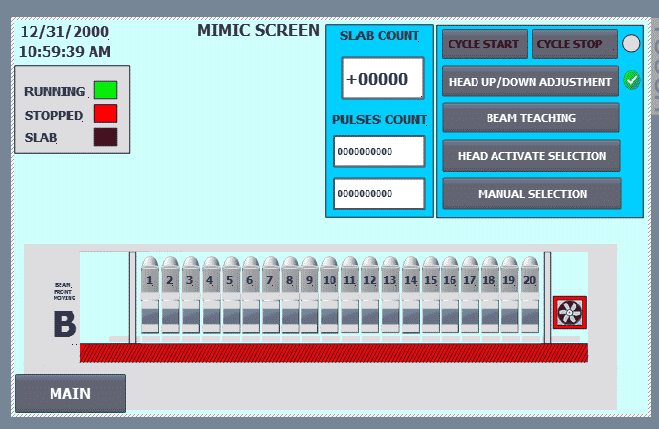

Granite Polishing Machine consists of 20 rotating heads and a moving conveyor in it. We developed a program to work it in auto mode where the entry and exit of slab after polishing will be done automatically. We used SIEMENS S7-1200 and KTP 1200 HMI hardware for automating the process. The working principle in the polishing machine is after starting the cycle a slab enters into the machine belt and beam starts moving horizontally. A sensor is placed in the entrance of belt to sense the slab entry and note the slab length.

After noting the start point and slab length the data is fed to PLC. When the slab reaches to the first head middle the head automatically moves down on to slab. Thus, the slab moves forward and remaining heads in the machine starts moving down when slab reaches to that particular head. Like this, the process continuous for all heads one by one.

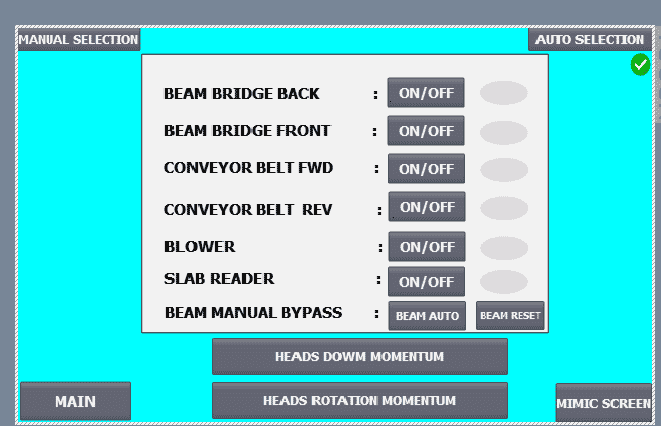

The above process i.e., polishing will continue for all slabs which are entering into the machine. We also developed manual setting operation of machine where each head can be operated manually.

Belt, Beam and Head rotation can also be operated manually.

+91 9030070085

+91 7801063999

#501C, Bankers Chambers,

A S Raju Nagar, Kukatpally,

Hyderabad Telangana -500 072.