Electric Motor is a critical equipment in any industry to convert electric energy to mechanical energy. Making of electric motor and to achieve correct output i.e. HP and its totally depends on engineering and design of motor. In this aspect, size of core plays very vital role and to achieve accurate lamination dimension. For maintaining all key features of motors, we have developed Automated logic to make accurate lamination, increase the productivity and maintain the quality.

Core Lamination cutting machine will be feed with 3mm metal sheet and is used to form a different type of lamination by using the different types of dies. However, for maintaining the accuracy and productivity of the laminated cores we have used PLC based automation.

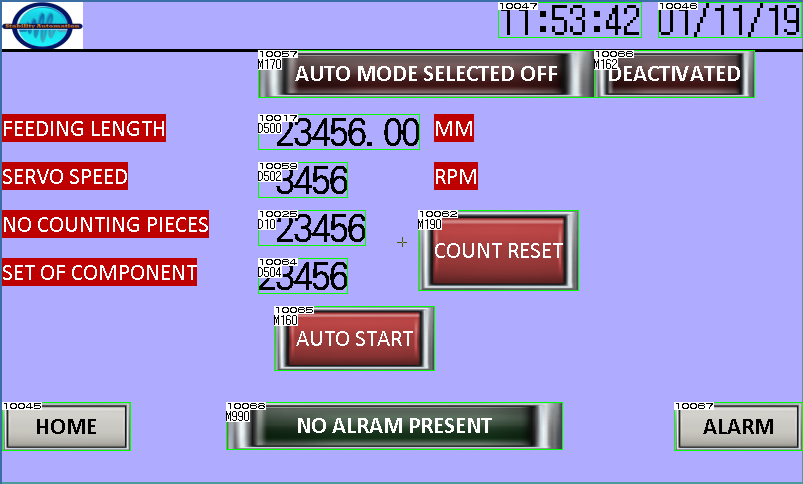

In laminated core cutting machine we also used the Servo Motor, HMI and Sensors. For maintaining the accuracy & reliability of cutting we have used Servo. As this machine is very heavy, we used CAM Sensor to signal as reference for punching. HMI is used for selection of different operations for different dies and it will be user friendly for an operator. So they can operate machine efficiently and easily.

+91 9030070085

+91 7801063999

#501C, Bankers Chambers,

A S Raju Nagar, Kukatpally,

Hyderabad Telangana -500 072.