A transformer is a device that can transfer electrical energy from one circuit to another through an inductively coupled conductor which is the Transformer Coil. Transformer testing is done for confirming the specifications and performance of an electrical power transformer. The transformer is the main part of an electrical distribution system so if it is not working properly then it will affect the distribution system. So, it has to go through numerous testing procedures. Some tests are done at the manufacturing location before delivering it to the customer. The need for transformer testing is to check the functioning of the transformer and to decrease the chance of failure.

To prove that the transformer meets customer’s specifications and design expectations, the transformer has to go through different testing procedures in manufacturer premises. Some transformer tests are carried out for confirming the basic design expectation of that transformer.

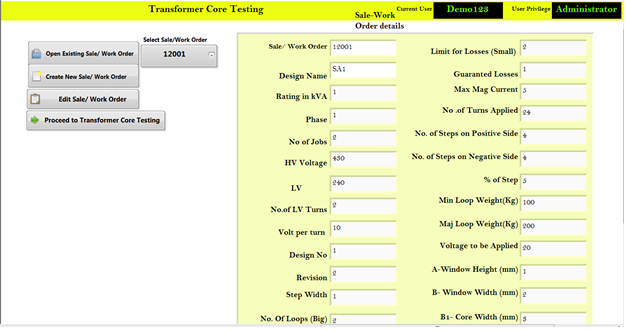

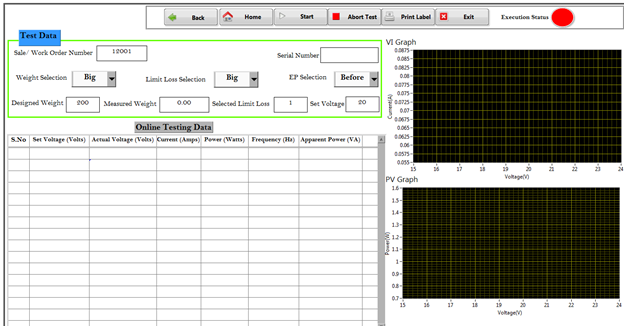

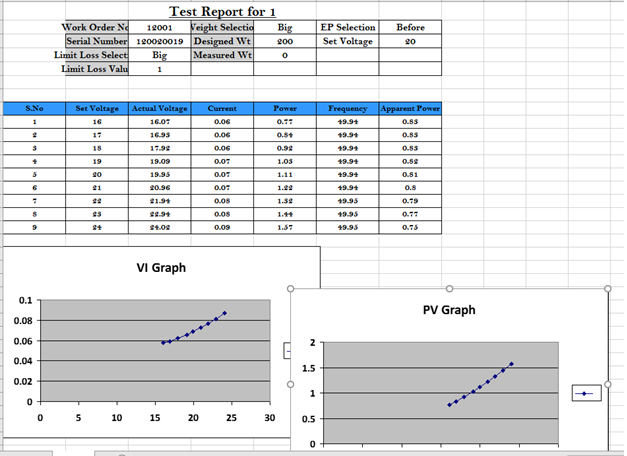

Stability Automation has developed Complete Automated Test Solution for Transformer Core System to test it at different voltage levels and report losses in testing. This system captures online weight of the system and also gives complete report. Result will be displayed in graph with V-I and V-P. This system will be used for quick testing of more no of systems.

In this system Stability Automation has used Power Analyzer to perform the testing and weighing machine is also used to weigh the Transformer. Below is the overview of the system:

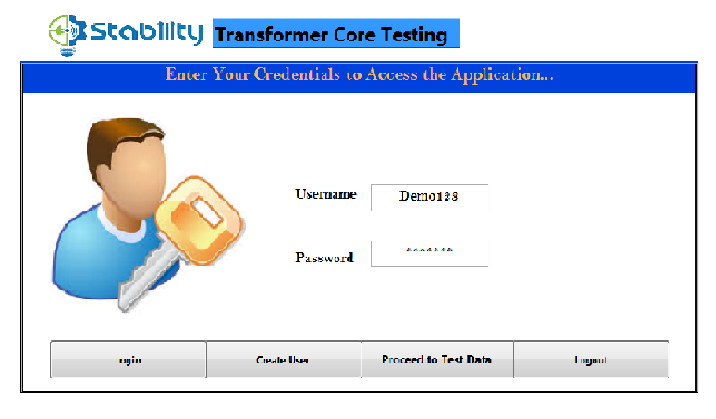

User Management: User Management system is used to differentiate the users of accessing the system. Like Administrator has access to whole process while operator or engineer has access to particular section in the system.

It can be seen that the appropriate range of tests will provide complete assurance that all materials and production processes within a transformer are correct. This in turn will guarantee that each and every transformer core tested is known to fully meet the required specification.

+91 9030070085

+91 7801063999

#501C, Bankers Chambers,

A S Raju Nagar, Kukatpally,

Hyderabad Telangana -500 072.