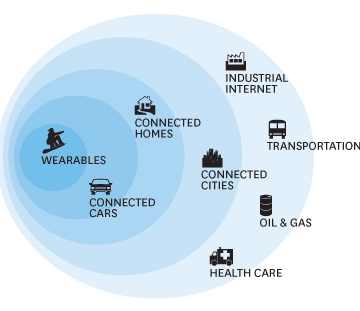

The Industrial Internet of Things originally described the IoT (Internet of Things) as it is used across several industries such as manufacturing, logistics, oil and gas, transportation, energy/utilities, mining and metals, aviation and other industrial sectors.

IIoT (Industrial Internet of Things) is fairly a new concept for industries, and it is presenting a huge opportunity in helping enterprises to operate more safely and productively while improving efficiency and reducing costs.

Still, many companies facing problems with the adoption of industrial IoT without knowing where to start and which automated processes will contribute to the highest increase in effectiveness.

Challenges:

Security

Security challenges for IIoT technologies are the biggest concern as the breaches affect both individuals and organizations vulnerable to financial and operational damage. As industrial companies using a variety of IIoT solutions, they are open to security concerns, lack of visibility, hack vulnerability, risks associated with IT/OT convergence, and insider threats. The main challenges are the lack of comprehensive cybersecurity solutions.

IIoT Integration

Another tricky challenge faced by IIoT implementation is the integration of information technology (IT) and operational technology (OT). And, it is important to securely integrate the two without data loss. Mostly, IoT devices are commonly developed as independent solutions, and in best-case scenarios, they are injected into the manufacturing process to become a part of the system. However, integration between information technology (IT) and operational technology (OT) lacks effective connectivity and synchronization. Therefore, it needs to replace either the entirety of their equipment or rely on faulty connectivity.

Connectivity and Visibility

The critical IIoT-implementation challenges are rooted in the lack of connectivity. IIoT machine management is a critical question, and it’s vital to monitor machines in real time as well as ensure those machines are performing at an optimal level to improve production. Increased visibility and better insights on the health of the machine is also critical in order to detect the abnormality and fix issues before they occur. IIoT machines are connected to different components, and there is often trouble in synchronizing as a result of Internet outages, power blackouts, and manual/technical errors. This will result in the removal of connected devices from the network, which affects the entire production process and can cost millions in damages.

Conclusion

IIoT challenges facing industrial companies today may seem overwhelming. But, overcoming these challenges offers game-changing business opportunities to improve productivity and growth for those companies. And, most of the IIoT implementation challenges can be resolved with monetary investment and a commitment to develop industry infrastructure and services aimed at comprehensive implementation. Supporting infrastructure components alongside the IoT technology is needed in order to speed up the IIoT revolution.