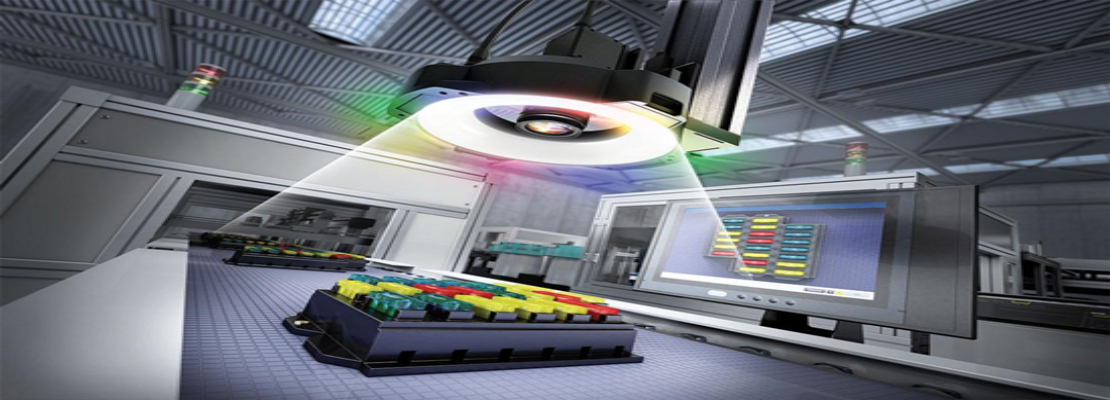

Vision inspection systems provide image-based inspection automated for your convenience for a variety of industrial and manufacturing applications. Though not a new technology, 2D and 3D machine vision systems are now commonly used for automated inspection, robot guidance, quality control and sorting, and much more. Visual Inspection Systems in Manufacturing gives more accurate result and reduce defect rejection.

Vision inspection systems can be used in any number of industries in which quality control is necessary. For example, vision systems can assist robotic systems to obtain the positioning of parts to further automate and streamline the manufacturing process. Data collected by a vision system can help improve efficiency in manufacturing lines, sorting, packing and other applications. In addition, the information captured by the vision system can identify problems with the manufacturing line or other function you are examining in an effort to improve efficiency, stop inefficient or ineffective processes, and identify unacceptable products.

Vision inspection systems, consist of several components that are common to most systems. Although each of these components serves its own individual function and can be found in many other systems, when working together they each have a distinct role in a machine vision system.

These components of machine vision systems typically include the following five elements:

The lighting system

The optical system or lens

The sensor

The vision processing system

The communications system

Stability Automation has worked on no. of Vision based projects below are the few case studies

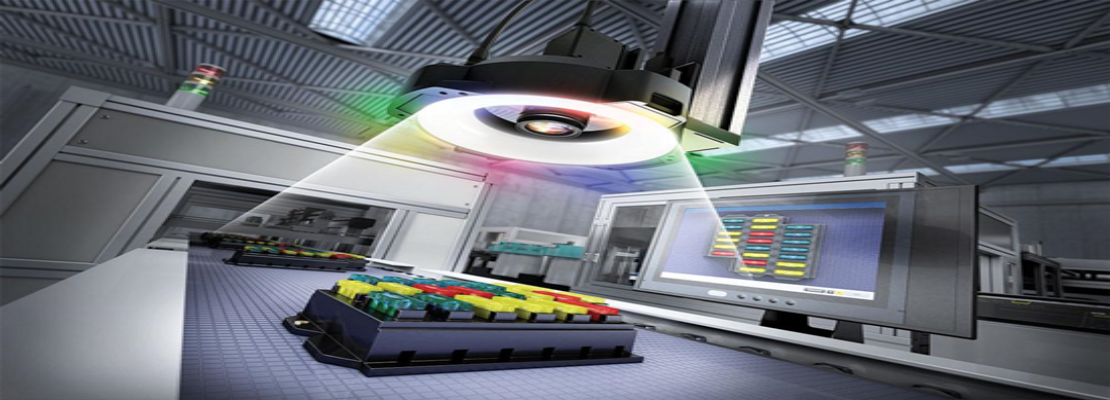

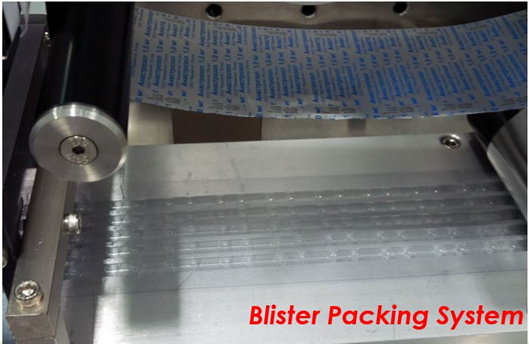

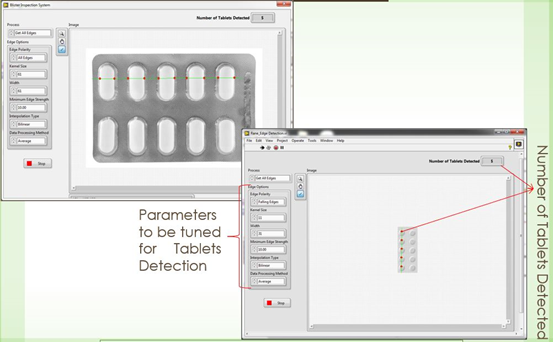

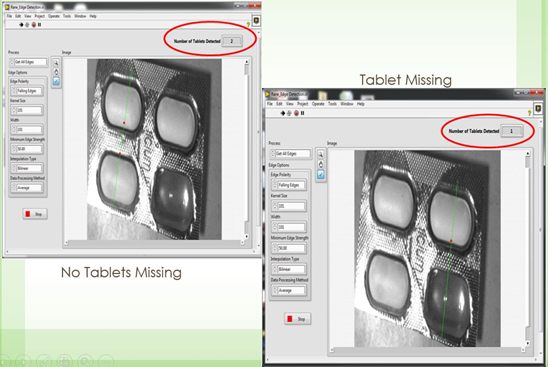

Case 1: Blister Inspection System

Blister Packing is typically used by pharmaceutical companies to package tablets and capsules. Given the need for accuracy and flawlessness with regard to the products as well as the packaging in the pharmaceutical industry, these blister packs need to be checked thoroughly.

A Vision based inspection system, installed on the packaging line, is the most efficient way to inspect and verify all the elements of a blister pack. It can be used to inspect all the types of blister packs commonly used by pharmaceutical companies. Additionally, it performs reliable inspection of any kind of aesthetic fault in the tablet or capsule.

Bliss vision inspection systems can detect:

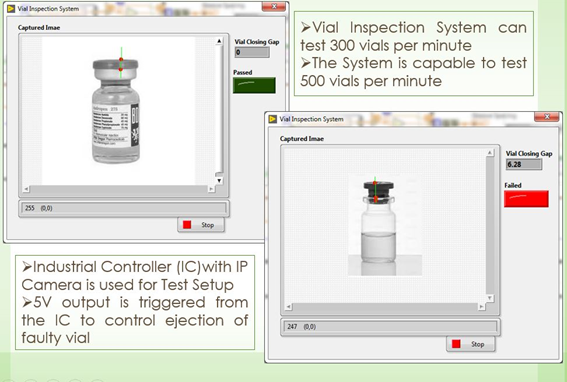

Case 2: Vial Inspection System

Automatic visual vial inspection machine ensures that the vials, after being sealed, for any defects regarding breakage, filling, or any other problems. This vial inspecting equipment helps with the detection of defective vials and hence can be rectified ensuring minimum loss. The inspection for any defects is carried out visually. The inspection machine for vials is a very important equipment for pharmaceutical applications as safety is the top most priority in pharmaceutical applications. Even the slightest of the defects can have huge repercussions on the application for which the vials are meant to serve and thus the vial inspection machine is considered an important machine in the pharmaceutical industries. The inspection machine checks for the condition of vials and its content whether they are safe for practical applications. In a visual inspection machine, the checking of vials is done with very little human intervention. It requires very little maintenance and performs the operation quite effectively.

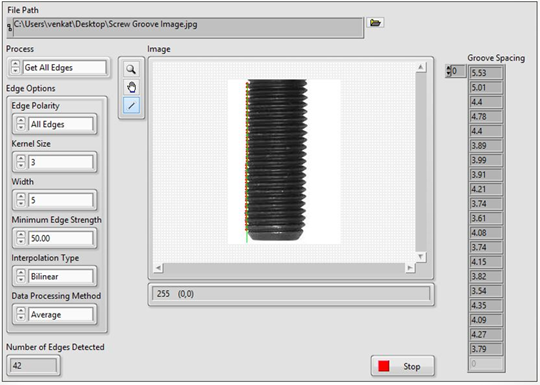

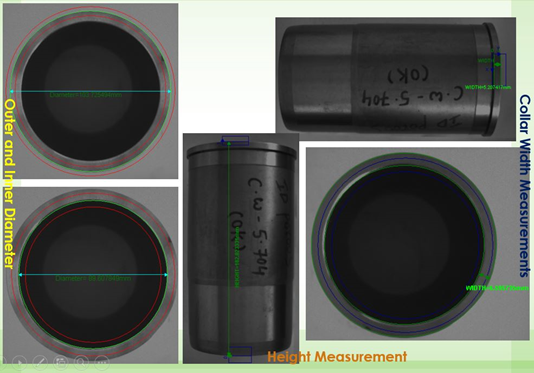

Case 3: Die-casting Inspection System

Die Casting Inspection System is a combination of Motion & Vision. The system has to move object to be inspected to a suitable position for various measurements. For Instance, to measure the Outer and Inner diamerter the object has to be presented to camera in a different view when compared to measure height.

Die-casting Inspection has to cater for the follwing Visua Inspection Parameters:

The System has to cater for the following Dimension Measurements:

Overall, the benefits of vision inspection systems, include, but are not limited to, production improvements, increased uptime, and reduction in expenses. Vision systems allow companies to conduct 100% inspection of parts for quality control purposes. This ensures that all products will meet the customers’ specifications. If you want to improve the quality and efficiency of your industry, a vision inspection system could be the answer for you.

+91 9030070085

+91 7801063999

#501C, Bankers Chambers,

A S Raju Nagar, Kukatpally,

Hyderabad Telangana -500 072.