Condition monitoring of transformers is the process of acquisition and processing of data related to various parameters of transformers so as to predict and prevent the failure of a transformer. This is done by observing the deviation of the transformer parameters from their expected values. Transformer failures could cause power outages, personal and environmental hazards and expensive rerouting or purchase of power from other suppliers. Transformer failures can occur due to various causes. Transformer in-service interruptions and failures usually result from dielectric breakdown, winding distortion caused by short-circuit withstand, winding and magnetic circuit hot spot, electrical disturbances, deterioration of insulation, lightning, inadequate maintenance, loose connections, overloading, failure of accessories such as OLTCs, bushings, etc. Integrating the ‘individual cause’ monitoring allows for monitoring the overall condition of transformer.

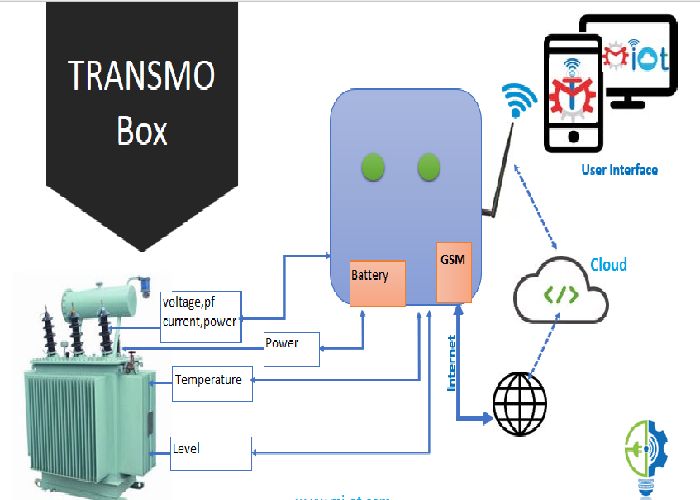

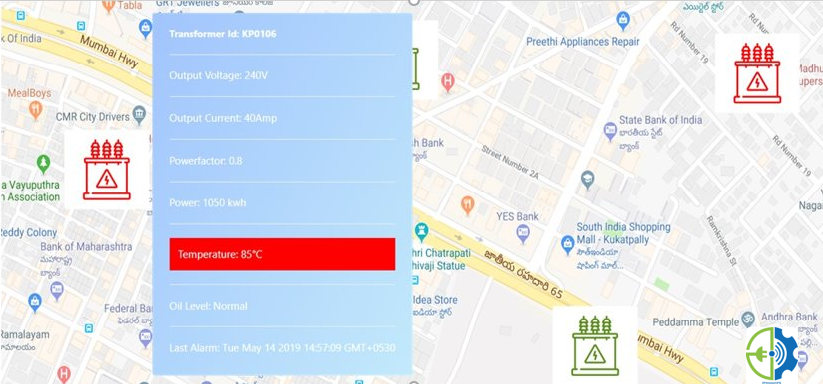

Thus, in order to monitor the parameters of Transformer we made a solution i.e., we used a hardware box called TRANSMO. This Product having high end software features for geographically located multiple transformers remote monitoring & control, devices, connections & users management, Alarms, trends & notifications, Failure prediction, demand forecast, data storage & security features and many more and It also consists of Industrial IoT gateway and Cloud based Software application.

TRANSMO box is Low Cost and Industrial grade reliable hardware. It will measure Transformer O/G Voltage (R, Y, B), Current (R, Y, B), Power & Power Factor, Oil Temperature, Oil Level & etc. It is having Inbuilt Battery for Power Backup & Power Failure.Power Supply will be connected from Transformer O/G Only.It support both GSM(Mobile) and Wi-Fi Communication for Data Transfer.Local Status Indication for device Health Status.

+91 9030070085

+91 7801063999

#501C, Bankers Chambers,

A S Raju Nagar, Kukatpally,

Hyderabad Telangana -500 072.